machineries

Welcome to our state-of-the-art flour milling facility, where tradition meets technology to deliver excellence.

With an impressive daily grinding production capacity of 220 tons, our mill combines advanced machinery with time-honored craftsmanship to produce flour of the highest quality—nutritious, consistent, and tailored to meet diverse culinary needs.

Take a closer look at the innovative equipment that drives our operations and ensures precision at every stage of production:

Precision Cleaning Technology: Our milling process begins with a rigorous cleaning stage powered by cutting-edge equipment, including vibrating screens, de-stoners, and magnetic separators. These advanced systems work in harmony to meticulously remove impurities such as stones, sticks, and metallic particles—ensuring that only the purest, highest-quality grains enter the production line. This commitment to precision not only protects our machinery but also guarantees the integrity and safety of every batch of flour we produce.

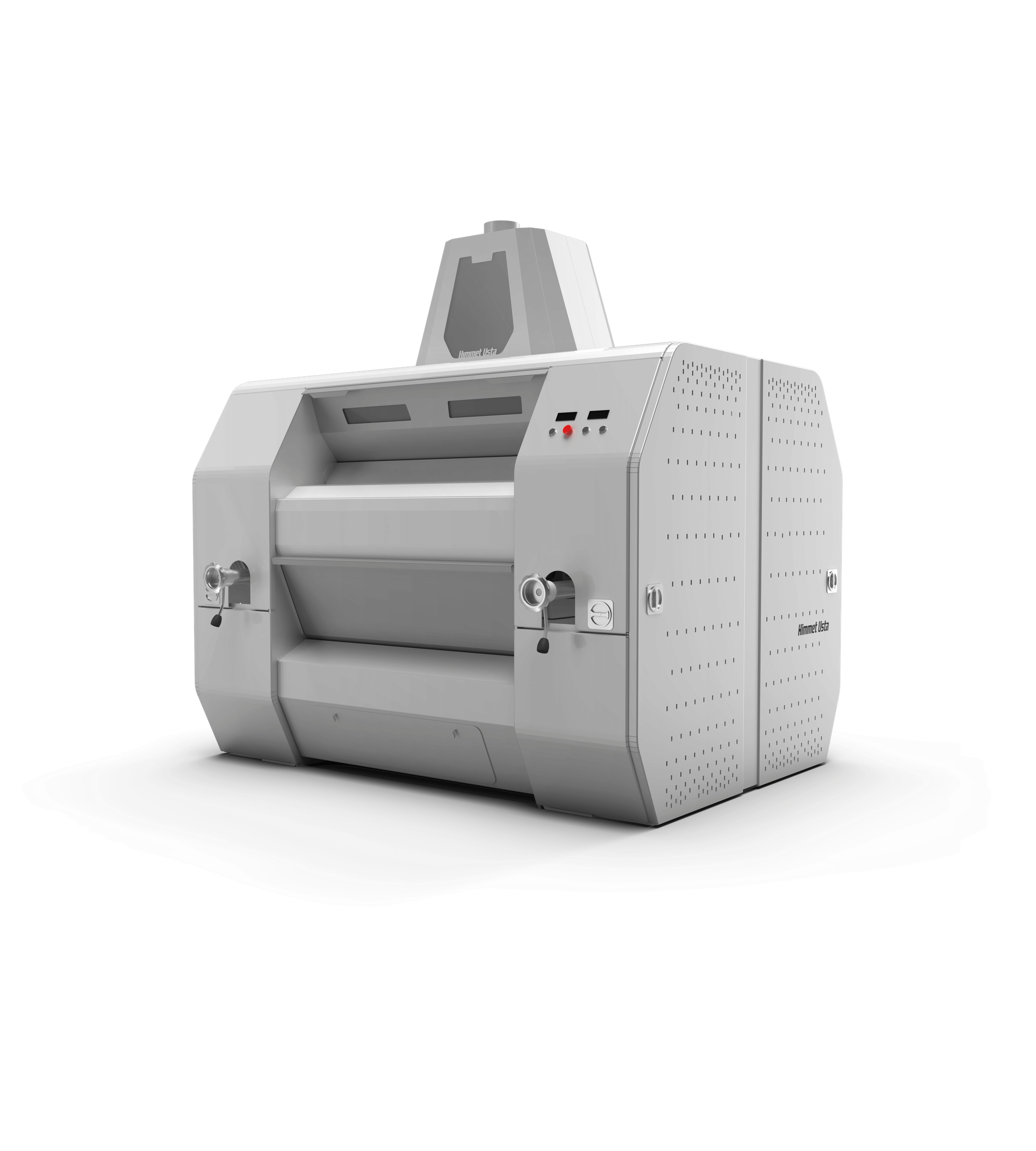

Next-Generation Milling Machines: At the core of our production facility lies a suite of next-generation milling machines, engineered for precision, efficiency, and consistency. Our roller mills and stone mills are equipped with advanced automation and real-time monitoring systems, allowing us to maintain optimal grinding performance and superior flour quality across every batch.

These machines are meticulously calibrated to preserve the nutritional integrity of the grain while achieving the perfect texture and fineness required for a wide range of baking and culinary applications. The result? We ensure that our flour meets the highest standards of purity, taste, and reliability every single time.

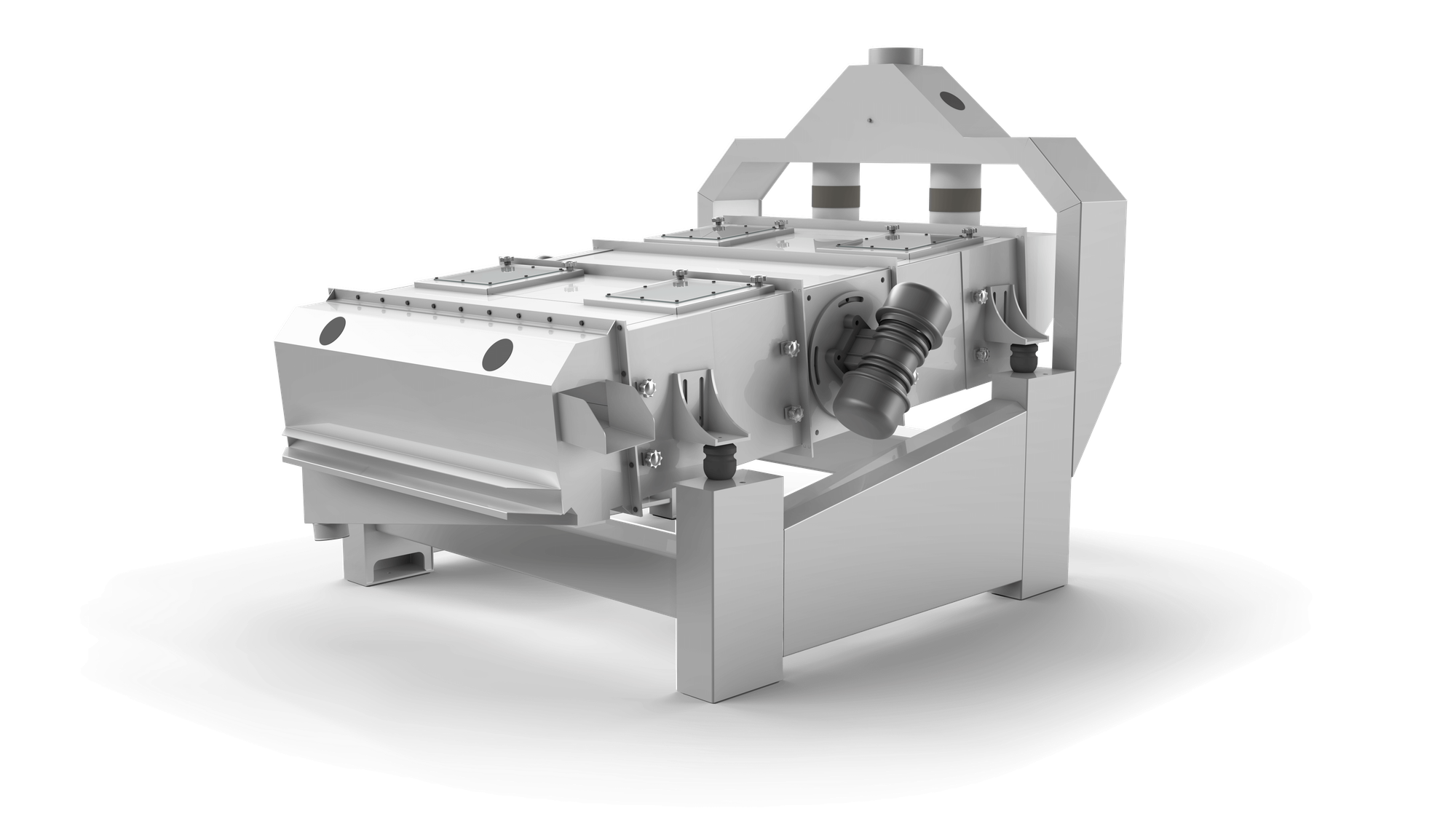

High-Efficiency Sifters and Sieves: Following the grinding stage, our flour is subjected to a meticulous sifting process designed to achieve optimal fineness and purity. Using high-efficiency sifters and specially designed sieves, we carefully sort the flour into different grades with great precision by using custom mesh sizes and controlled airflow systems.

This advanced filtration not only removes residual bran and microscopic impurities but also ensures consistency in texture and quality—meeting the exacting standards required for both artisanal baking and industrial food production.

Advanced Purification Systems: To ensure maximum purity and milling efficiency, our facility incorporates a state-of-the-art Drum Detacher—a critical component in the flour refinement process. This advanced system separates the starchy part of the grain from the bran before sifting, which lessens the strain on the equipment that comes after and By optimizing the texture and consistency of the milled product, the Drum Detacher plays a vital role in delivering flour that meets the highest standards of quality, hygiene, and performance.

Automated Packaging Solutions: Once milled and sifted, our flour is packaged with precision using automated bagging machines and streamlined conveyor systems. These advanced systems ensure accurate filling, secure sealing, and consistent weight control—preserving the freshness, purity, and shelf life of every product.

To maintain traceability and meet regulatory standards, each bag is labeled using a food-grade industrial printer, which applies clear, durable, and hygienic markings such as batch codes, production dates, and product details. The result ensures compliance with food safety regulations and provides transparency for our customers.

Our packaging process is reinforced by rigorous quality control protocols, guaranteeing that every product leaving our facility meets the highest standards of hygiene, safety, and presentation—ready for both domestic and international markets.

Intelligent Automation and Control Systems: Our flour mill operates with intelligent automation and advanced control systems that oversee and optimize every stage of production in real time. These integrated technologies continuously monitor key parameters—from machine calibration and temperature regulation to grain flow and flour quality—ensuring seamless performance and immediate responsiveness.

By automatically adjusting settings and analyzing output data, our systems deliver unmatched efficiency, consistency, and precision. This smart infrastructure enhances productivity and guarantees that every batch of flour meets our exacting standards for purity, texture, and nutritional value.

Comprehensive Quality Assurance: Quality is our top priority, which is why we employ cutting-edge quality control equipment such as moisture meters, gluten analyzers, and particle size analyzers. These tools enable us to maintain the highest standards of quality and consistency in every batch of flour we produce.

Experience Innovation and Craftsmanship in Every Grain

Step into the heart of our flour mill, where centuries-old tradition meets cutting-edge technology to produce flour of exceptional quality and purity. Our facility is a testament to precision and progress—engineered to deliver consistent results while honoring the artisanal roots of milling.

With a production system tailored for flexibility, we have the capacity to manufacture custom flour varieties that align precisely with your specifications and unique preferences. Whether you require specialized blends for baking, industrial-grade flour for large-scale production, or nutrient-rich options for health-conscious consumers, we’re equipped to meet your needs with accuracy and care.