flour milling operation

At Flour and Bread Product Barakat Hariwa, producing high-quality wheat flour is more than a process—it’s a precision-driven craft rooted in innovation, tradition, and attention to detail. We carefully engineer every step of our milling operation to uphold the highest standards of purity, nutrition, and consistency.

Here’s a comprehensive overview of the key components of our modern flour milling system, where advanced technology and expert craftsmanship work together to transform premium wheat into flour that meets the needs of bakers, chefs, and food producers across Afghanistan and beyond.

From Field to Flour: Our Commitment to Purity and Precision

At Flour and Bread Product Barakat Hariwa, quality begins long before the milling process—it starts at procurement. Raw grain often contains impurities introduced during harvesting, transportation, or storage. That’s why we implement a meticulous cleaning and inspection protocol to eliminate foreign contaminants and ensure only the purest, highest-grade wheat enters our production line. This foundational step directly impacts the consistency, safety, and nutritional value of the flour we produce.

Our milling process is designed to separate the endosperm from the bran and outer casing with exceptional control. By separating each step, we can adjust important factors like how fine the flour is, how much starch is damaged, and how the flour flows, leading to flour that meets high standards for texture, performance, and purity. Our state-of-the-art facility empowers us to deliver consistent quality across every batch.

Wheat arrives at our mill year-round, with peak activity during the July harvest season. We source local wheat from Afghanistan’s western provinces—including Herat, Helmand, and Badghis—and import premium varieties from the northern shores of Kazakhstan.

Each incoming truckload is individually sampled and rigorously tested for:

- Moisture content

- Test weight

- Foreign material

- Insect infestation

- Sprout damage

We immediately reject any shipment that does not meet our strict quality standards, ensuring we use only the best raw materials in our production.

Once approved, the wheat is unloaded into one of our three grain unloading pits. During harvest and winter, any wheat with moisture levels above 13.5% is transferred to our silos, where it is carefully rested below 13.5% for safe, long-term storage.

The dried grain is then moved to our concrete silos, where it undergoes disinfection and cooling to preserve its integrity and prevent spoilage. This controlled environment ensures that our wheat remains fresh, safe, and ready for precision milling at any time.

OUR MILLING PROCESS

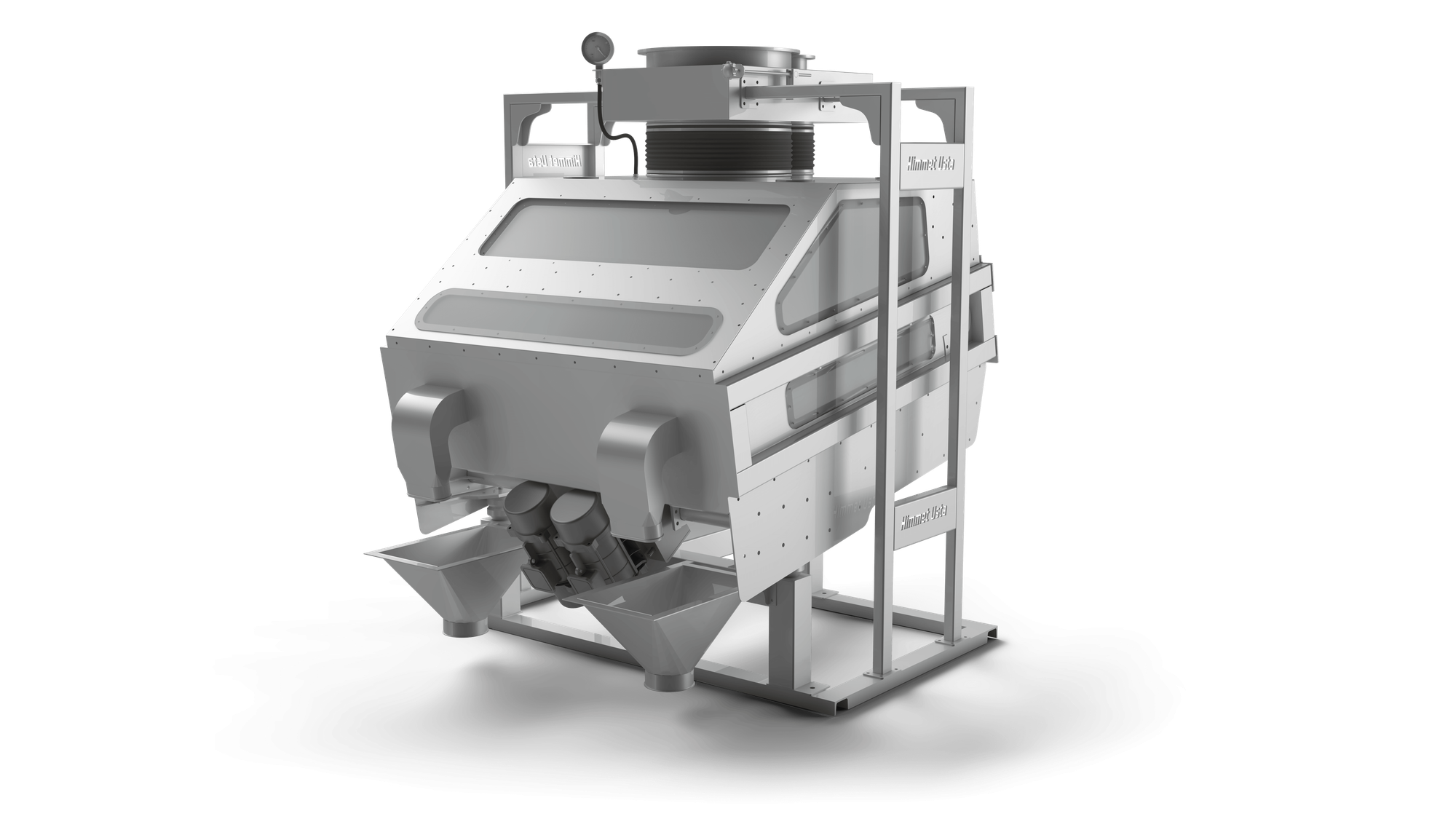

Cleaning and Conditioning: Before milling begins, wheat is thoroughly cleaned to remove impurities picked up during harvesting, transport, or storage. Using vibrating screens, de-stoners, and magnetic separators, we ensure only the purest grains enter production. Conditioning then adjusts moisture levels for optimal milling performance and consistent flour quality.

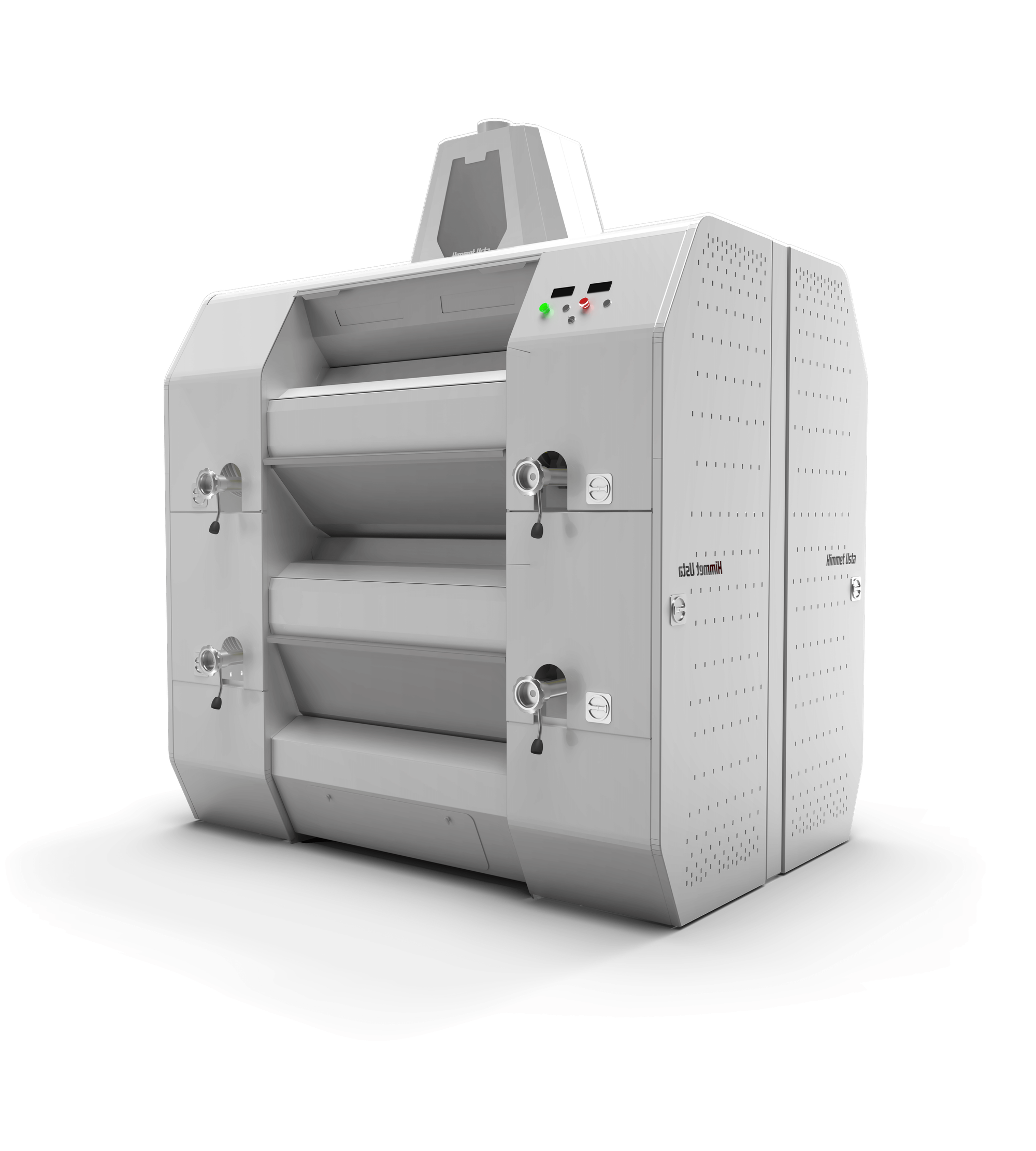

Milling: After cleaning, the grains are ground into flour using roller mills. These machines are equipped with advanced automation and monitoring systems that optimize grinding efficiency and ensure consistent flour quality across every batch.

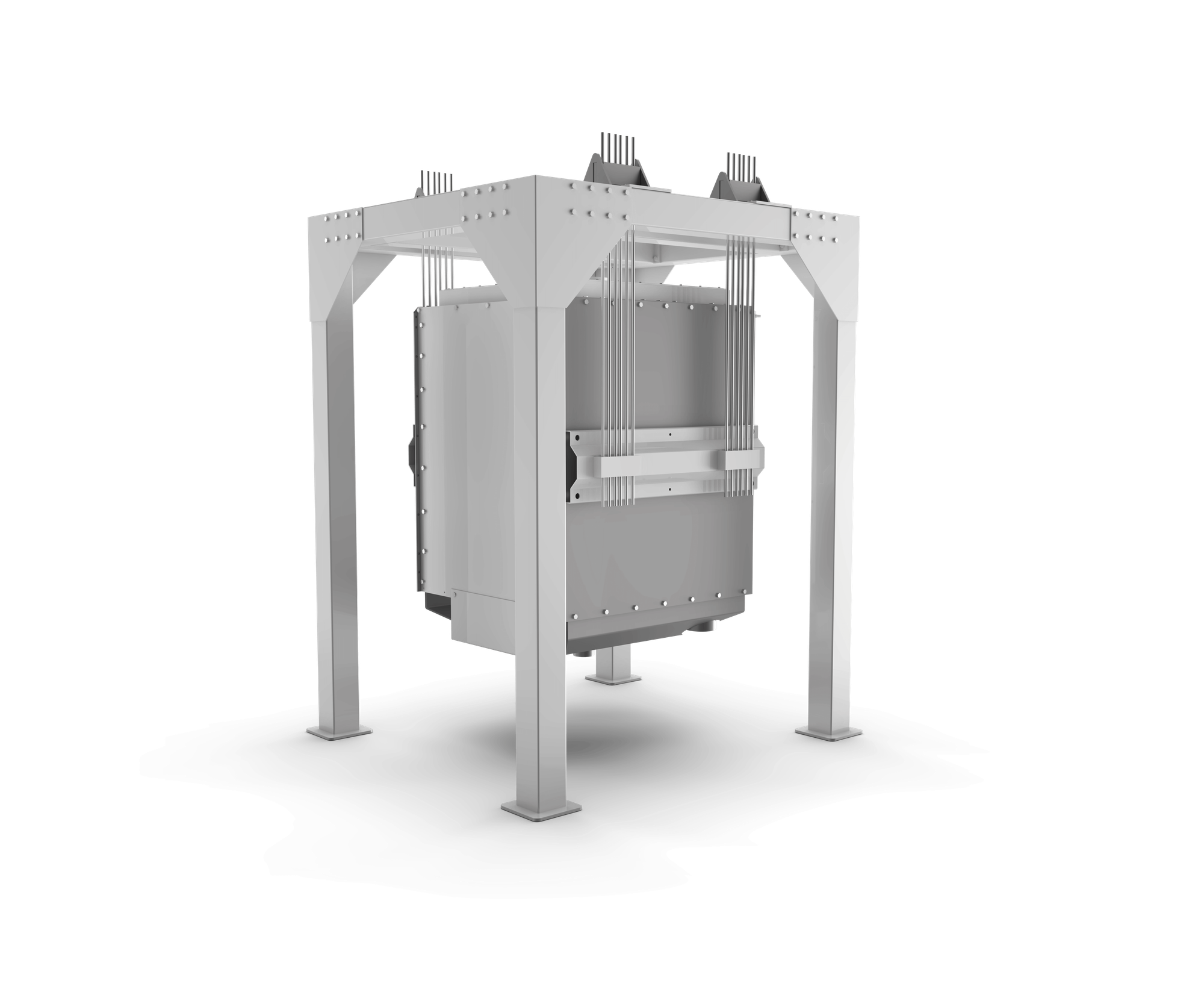

Sifting and Purifying: After milling, the flour is carefully sifted and purified to remove any remaining bran or impurities. Using high-tech sifters, sieves, and purifiers, we apply precise mesh sizes, airflow control, and density separation to achieve the desired texture and purity—ensuring every batch meets our premium quality standards.

Quality Control: Quality is central to every step of our milling process. We use moisture meters, gluten analyzers, and particle size analyzers to monitor key parameters and ensure consistency. Backed by automated control systems, our operations maintain strict quality standards—delivering flour that’s safe, reliable, and high-performing.

Packaging and Distribution: Once milled and sifted, our flour is packaged using automated bagging machines and conveyor systems that ensure accurate filling and secure sealing. This preserves the freshness and purity of every batch. During packaging, quality control checks are performed to detect any defects or contaminants—guaranteeing safe, high-quality flour ready for distribution.

Automation and Technology: At Flour and Bread Product Barakat Hariwa, our mill uses smart automation systems to manage every stage of production. From adjusting machine settings to monitoring flour quality in real time, automation ensures efficiency, consistency, and full control—even during peak harvest seasons.

Sustainability and Environmental Considerations: At Flour and Bread Product Barakat Hariwa, we prioritize sustainable milling practices by using energy-efficient machinery, implementing waste reduction measures, and supporting recycling initiatives. These efforts help minimize environmental impact and ensure responsible, long-term operations that benefit both our community and the planet.

Finished Flour

Finished flour is continuously collected from the sifters, fortified and blended, then passed through a re-bolt sifter for final purification. It’s automatically weighed before packaging to ensure accuracy.

Throughout the day, our in-house lab tests flour samples for protein, gluten, zeleny, moisture, ash, and water absorption—guaranteeing consistent quality.

Once approved, the flour is loaded into 25-ton trucks, scanned for weight, and dispatched for on-time delivery, day or night.